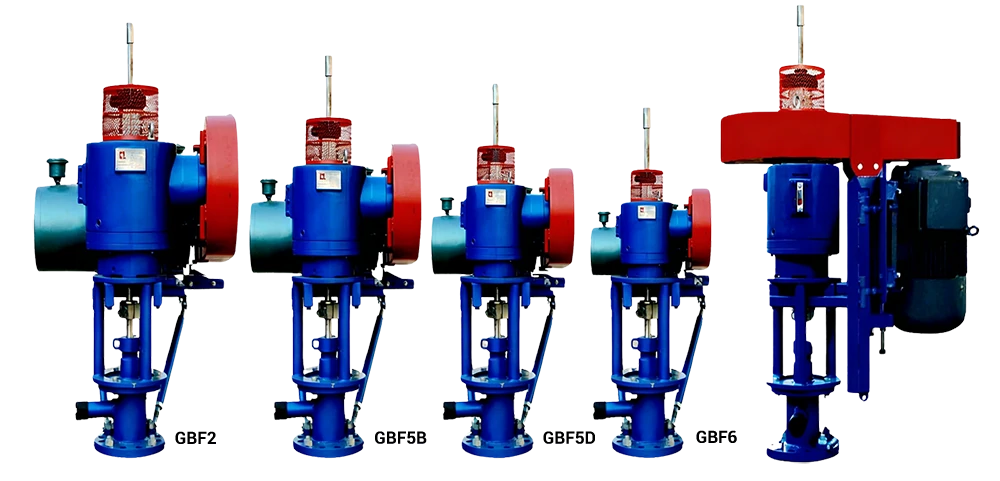

Surface Drive System

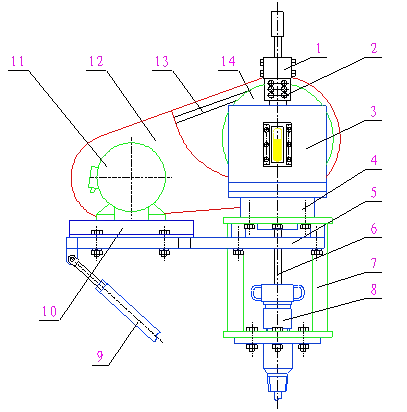

The surface drive is a specific facility to suspend and rotate the sucker rod, which in turn drives the downhole PC pump. Then fluid can be brought to the surface by the continuous movement of rotor within stator. When the unit is stop, the surface drive head absorbs reversion torque and prevents thread off. The mainly comprised parts are shown in fig 2.

Motor

A Y series three-phase asynchronous motor is screwed tight on the motor skid and by changing the location of the motor, V-belt tightness can be adjusted effectively. Technical specifications are shown in table 1.

Table 1 Primary Specification

|

Model |

Rated Power kW |

Rated Voltage V |

Rated Current A |

Output Speed rpm |

Power Factor cosφ |

Efficiency % |

|

Y225M-4 |

45 |

380 |

84.7 |

1470 |

0.87 |

92.8 |

|

Y200L-4 |

30 |

380 |

56.8 |

1470 |

0.87 |

92.2 |

|

Y180L-4 |

22 |

380 |

42.5 |

1470 |

0.86 |

91.5 |

|

Y160L-4 |

15 |

380 |

30.3 |

1460 |

0.85 |

88.5 |

|

Y200L-6 |

22 |

380 |

44.6 |

970 |

0.83 |

90.2 |

|

Y180L-6 |

15 |

380 |

31.4 |

970 |

0.81 |

89.5 |

|

Y160L-6 |

11 |

380 |

24.6 |

970 |

0.78 |

87.0 |

|

Y132M-4 |

7.5 |

380 |

15.4 |

1440 |

0.85 |

87.0 |

|

Y160M-6 |

7.5 |

380 |

17.0 |

970 |

0.78 |

86.0 |

Downhole PC Pump

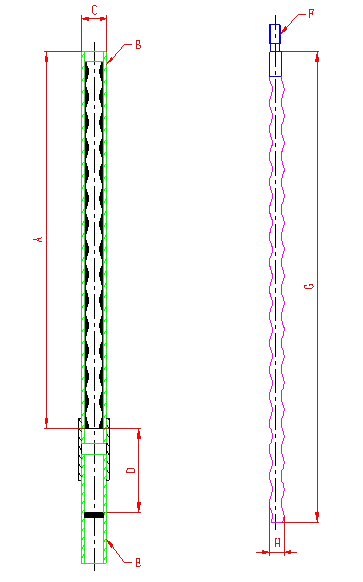

The PC pump brings the fluid from downhole to the surface and discharges it under a certain pressure. It consists of a rotor and a stator.(see fig14) The dimensions of rotor and stator are shown in table 13.

Downhole PC Pump Specifications

|

Model |

Rated Displacement |

Lifting Capacity |

||||

|

ml/r |

m3/d@100r |

bbl/d@100r |

Grade |

Height (m) |

Height (Ft) |

|

|

LB40-21 LB40-27 LB40-42 |

40 |

5.8 |

36 |

21 27 42 |

960 1200 1900 |

3100 3900 6200 |

|

LB50-12 LB50-27 LB50-40 |

50 |

7.0 |

44 |

12 27 40 |

600 1200 1800 |

1900 3900 5900 |

|

LB75-12 LB75-21 LB75-27 LB75-40 |

75 |

10.8 |

68 |

12 21 27 40 |

600 960 1200 1800 |

1900 3100 3900 5900 |

|

LB120-12 LB120-27 LB120-36 LB120-40 |

120 |

17.3 |

109 |

12 27 36 40 |

600 1200 1600 1800 |

1900 3900 5200 5900 |

|

LB190-27 LB190-33 LB190-40 |

190 |

27.4 |

172 |

27 33 40 |

1200 1500 1800 |

3900 4900 5900 |

|

LB200-25 LB200-33 LB200-40 |

200 |

28.4 |

181 |

25 33 40 |

1150 1500 1800 |

3800 4900 5900 |

|

LB300-21 LB300-27 |

300 |

43.2 |

272 |

21 27 |

960 1200 |

3100 3900 |

|

LB400-20 LB400-30 |

400 |

57.6 |

362 |

20 30 |

910 1300 |

2900 4200 |

|

LB500-14 LB500-21 |

500 |

72.0 |

453 |

14 21 |

640 960 |

2100 3100 |

|

LB600-12 LB600-14 LB600-21 |

600 |

86.4 |

543 |

12 14 21 |

600 640 960 |

1900 2100 3100 |

|

LB800-16 |

800 |

115.2 |

725 |

16 |

730 |

2400 |

|

LB1100-10 LB1100-12 LB1100-14 LB1100-16 |

1100 |

158.4 |

996 |

10 12 14 16 |

460 550 640 730 |

1500 1800 2100 2400 |

|

LB1400-14 |

1400 |

210.6 |

1325 |

14 |

640 |

2100 |

|

LB1600-12 |

1600 |

230.4 |

1450 |

12 |

550 |

1800 |

|

LB230DT27 LB230DT40 LB230DT50 |

230 |

33.1 |

208 |

27 40 50 |

1200 1800 2300 |

3900 5900 7500 |

|

LB375DT27 LB375DT33 LB375DT40 |

375 |

54.0 |

340 |

27 33 40 |

1200 1500 1800 |

3900 4900 5900 |

|

LB460DT27 LB460DT33 |

460 |

66.0 |

417 |

27 33 |

1200 1500 |

3900 4900 |

|

LB580DT18 LB580DT21 LB580DT27 LB580DT33 |

580 |

83.5 |

525 |

18 21 27 33 |

820 960 1200 1500 |

2700 3100 3900 4900 |

|

LB800DT20 |

800 |

115.2 |

725 |

20 |

910 |

2900 |

|

LB990DT14 |

990 |

142.6 |

897 |

14 |

640 |

2100 |

|

LB1200DT16 LB1200DT21 |

1200 |

172.8 |

1090 |

16 21 |

730 960 |

2400 3100 |

|

LB2000DT16 |

2000 |

288.0 |

1810 |

16 |

730 |

2400 |

|

LB1100TT14 LB1100TT18 LB1100TT21 LB1100TT27 |

1100 |

158.4 |

9960 |

14 18 21 27 |

640 820 960 1200 |

2100 2700 3100 3900 |

Rubber

After years study and development, stator rubber of our PC Pump has achieved a wonderful facility of production. International advanced rubber laboratory has been built. Advanced stator rubber formula can be developed all by ourselves. Rubber performance test and rubber impregnation technology have gained great success.

Table 15 Main Rubber Formulas for Stator

|

Code |

Rubber Type |

Application |

|

GY-1 |

Simple oil |

Used in the petroleum containing water and CO2. Below 80℃. |

|

GY-2 |

Clean oil |

Used in the fluid containing aromatics and CO2. Below 90℃. |

|

GY-3 |

Viscous and sandy oil |

Moderate acrylonitrile cut. Used in fluid with high sand cut and water. Below 120℃. |

|

GY-4 |

Hightemperature 130℃ |

Used in fluid containing CO2 and H2S with good mechanical property. Below 130℃ |

|

GY-5 |

Hightemperature 150℃ |

Used in fluid containing H2S. Working temperature reaches up to 150℃.Perfect mechanical property. |