Surface-Driven Progressing Cavity Pump Application in Coalbed Methane Wells (1500–2000 m Depth, 8–15 m³/day Water Production)

Rubber Material Selection for Stator Liners

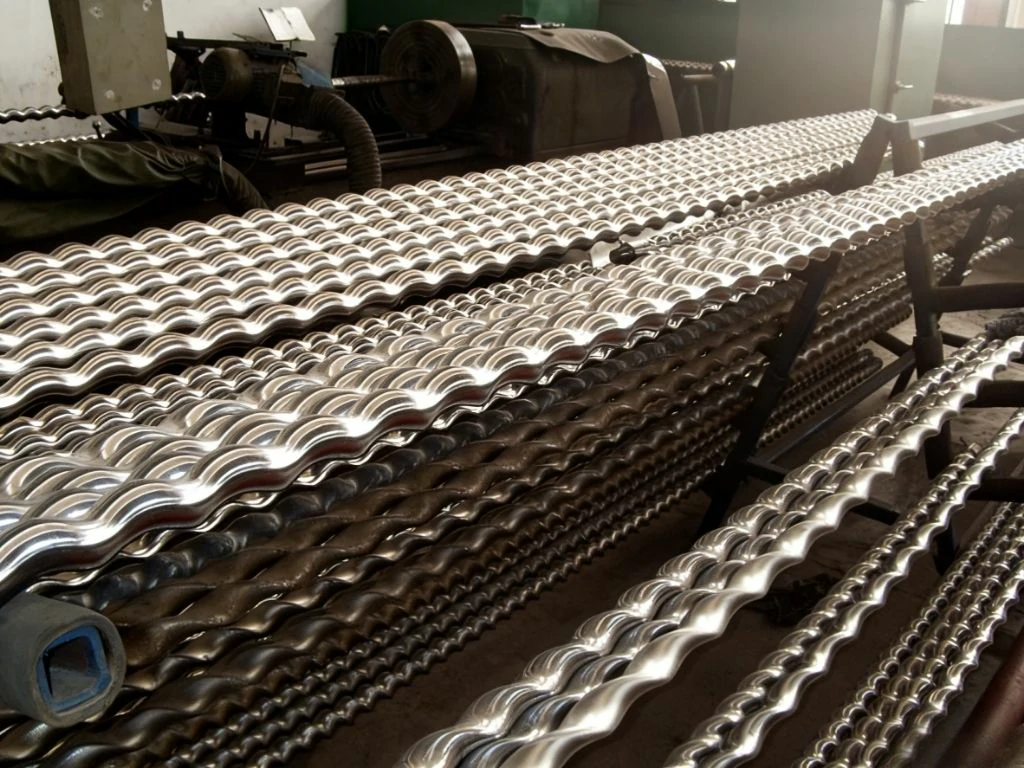

The stator rubber is critical for pump durability. In Shanxi’s CBM wells (1500–2000 m depth, 8–15 m³/day water production), HNBR (Hydrogenated Nitrile Butadiene Rubber) is preferred due to its:

- Anti-Gas Invasion Resistance: Prevents swelling from high gas content.

- Anti-Abrasion Performance: Withstands coal fines (0.1–0.5 mm) with hardness Shore A 75 ± 2.

- Temperature Adaptability: Stable up to 120°C.

- Service Life: 12–18 months (longer than NBR).

Recommended PCP Model Selection

GLB120-14 (1500–1800 m depth, 8–15 m³/day water):

- Pump diameter: 120 mm, Stator stages: 14 (140 m lift/stage).

- Motor power: 15–22 kW (18.5 kW for 1500 m, 22 kW for 1800 m).

- Advantages: Balanced performance, low torque, cost-effective maintenance.

GLB200-27 (1800–2000 m depth, 10–20 m³/day water):

- Pump diameter: 200 mm, Stator stages: 27 (270 m lift).

- Motor power: 22–37 kW (30 kW for 1800 m, 37 kW for 2000 m).

- Advantages: Ideal for deeper wells, enhanced gas-handling, longer service life.

Motor Configuration

- GLB120-14: 15–22 kW motor with VFD (Variable Frequency Drive) for speed optimization (200–300 RPM).

- GLB200-27: 22–37 kW motor with overload protection (thermal sensors).

- Energy Efficiency: VFD reduces power consumption by 15–25%.

Operational Practices

- Installation: Centralizers every 3–5 tubing joints, anchor tools to prevent pump movement.

- Maintenance: Replace stator every 12–18 months, monitor current/torque daily.

- Troubleshooting: Gas lock (install gas separator) or coal fines accumulation (use screen filters).