Coiled Tubing Work and Service

At present, the company is equipped with two sets of advanced coiled tubing operation units, namely vehicle-mounted and skid-mounted. Through advanced coiled tubing equipment, a high-quality service team, a complete set of downhole operation tools, a powerful technical support system and scientific and standardized management, it can carry out sand flushing, unblocking, negative pressure return drainage and salvage operations. Moreover, it can provide coiled tubing drag acidizing, sandblasting perforation fracturing, switch sliding sleeve fracturing, logging and jet radial drilling services.

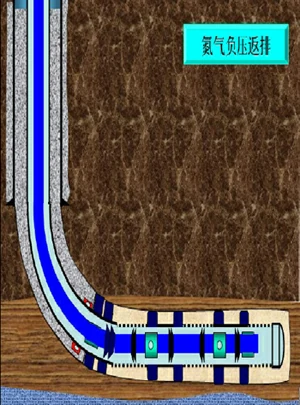

Coiled tubing Nitrogen Flowback

It can be used for inducing injection when new Wells are put into production, testing for production, and the return of well pressure fluids (including residual fluids and fracturing fluids).

Features:

- Compared with conventional suction and air lift methods, it is safer and more reliable, has a shorter operation cycle and higher efficiency;

- Continuous unloading gradually reduces the back pressure at the bottom of the well, minimizing damage to the oil layer.

- The gas injection volume and liquid discharge speed can be adjusted, making construction convenient and flexible with high controllability.

Coiled Tubing Fishing

The fish that have fallen from the bottom of the well can be retrieved, including the oil pipe, casing, drill pipe, bridge plug, bottom well motor, wire rope section, cable section and the coiled oil pipe itself.

Features:

- It generates significant axial tensile or impact forces in vertical Wells or highly inclined Wells, especially in horizontal Wells, facilitating the removal of trapped objects from underground Wells and enhancing the success rate of salvage operations;

- During the salvage process, various flushing fluids, including nitrogen and acid, can be circulated to conduct well cleaning and salvage simultaneously, preventing the falling fish from being stuck again;

- The top of the fallen fish can be subjected to high-pressure flushing, spraying or dissolving of sand, mud, scale and other debris before being caught, and the catching effect is good.

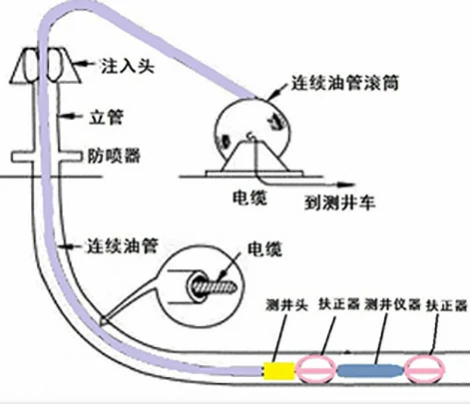

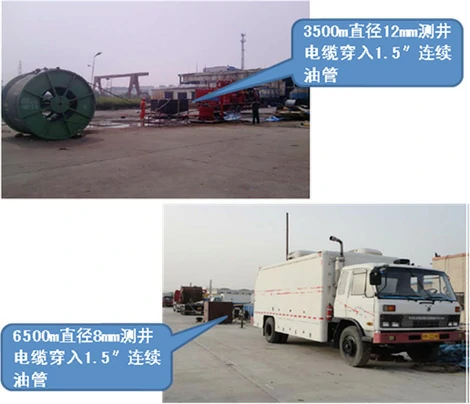

Coiled Tubing Logging

Logging cables are inserted into coiled tubing, equipped with corresponding downhole tools and joints, and connected to logging instruments. The logging instruments are then sent to horizontal Wells or highly deviated Wells for testing. It can be applied in logging processes such as production logging and open-hole logging, and can simultaneously pump liquids to achieve circulation.

Features:

- It can transport well logging instruments over long distances in large slopes and horizontal Wells;

- It enables logging tools to pass through short-distance helical twisted pipe sections;

- Better protection of logging cables, quick, simple and convenient replacement of logging tools;

- It can operate under pressure or with liquid flow, and is safe and reliable.

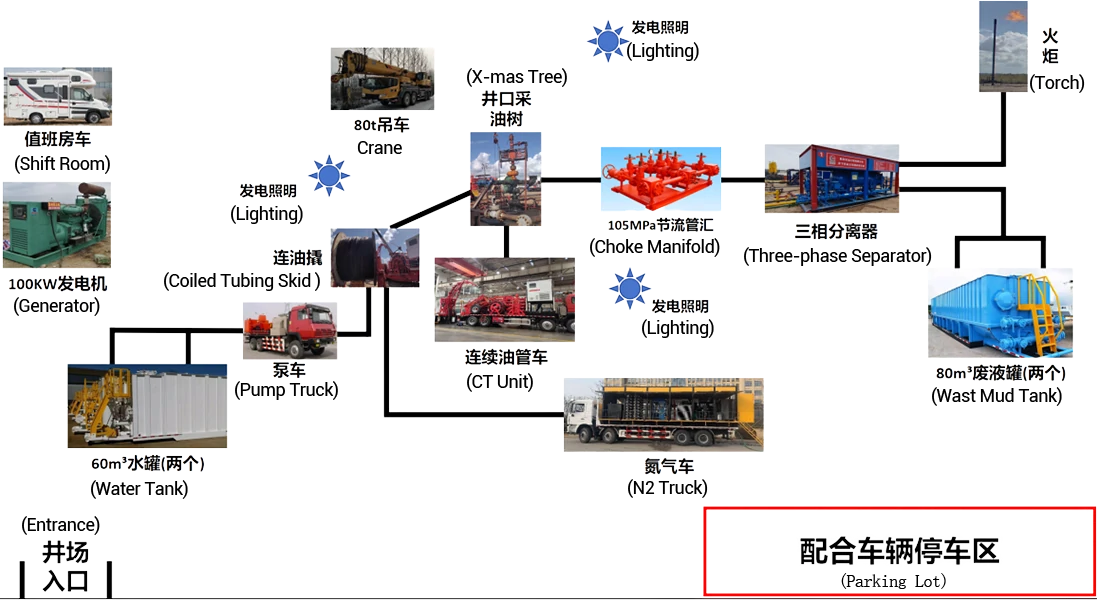

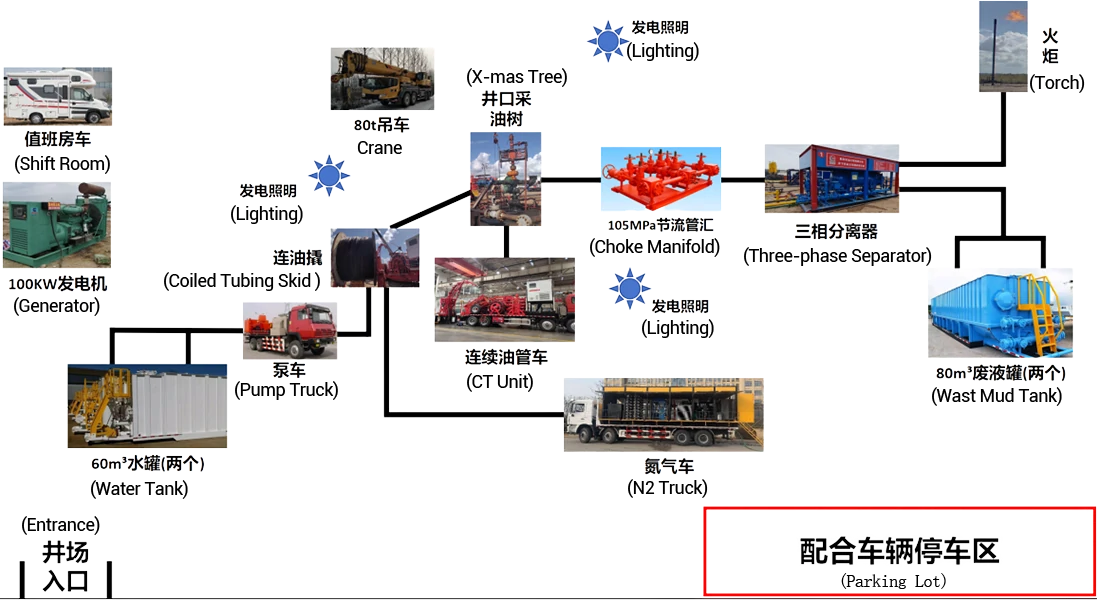

The Equipments Layout in the Process of Coiled Tubing Operation

|

No.

|

Name

|

Specification Parameters

|

Pictures

|

|

1

|

Coiled Tuibng Main Equipment

|

Integrated trailer type;

Inject head lifting force of 100000 pounds and betting force of 50000 pounds;

Drum capacity 1 3/4 "-8000m, 2" -6400m;

Spray box 4 1/16 "-15K psi;

Blowout preventer 5 1/8 "-15K psi

|

|

|

2

|

Continuous Oil Tubing

|

Length 7000m;

Outer diameter size 1 3/4 ";

Equal wall thickness (0.204in)

Pressure bearing 10K psi

|

|

|

3

|

Coiled Tuibng

|

Length 7000m;

Outer diameter size 1 3/4 ";

Variable wall thickness (0.204-0.188-0.175-0.156in)

Pressure bearing 10K psi

|

|

|

4

|

Mixed Liquid Trailer Pry

|

Exit 4 "206 is controlled by a gate, with two exits located at the tail of the pry bar;

Import 4 "206 union, with 3 inlet ports on each side of the lever, and a gate for separate control;

Two independent mixing tanks, each with 75bbl;

Can independently supply water and liquid;

Centralized control of the control panel;

Flow meters are suitable for diesel, chemical agents, naphtha, etc

|

|

|

5

|

Piston Pump Trailer Pry

|

Export 2 "1502 Union B

Import 4 "206 Union P

Dual machine dual pump, 600HP * 2;

Single pump displacement 40-600L/min (0.26-3.77BPM);

The maximum working pressure is greater than 10K psi;

Corrosion and oil resistance;

Equipped with a remote control box, capable of remote operation and data collection

|

|

|

6

|

Nitrogen Generator Trailer Pry

|

Specification and model: MZD-1200/500-95% - C

Maximum displacement of 1200m3/h (flow: 706 scfm);

Maximum pressure 50MPa (presion: 7250psi);

Purity adjustable from 95-99% (pureza: 95% -99%)

Export 2 "1502 Union B

Export equipped with one-way valve 2 "1502 10000psi

|

|

View More Specification Parameters